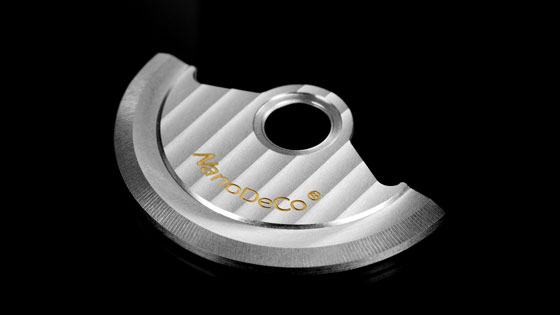

With its patented solution, Positive Coating offers a cost-effective alternative to the rhodium plating of monobloc tungsten oscillating weights.

When the price of rhodium reaches unprecedented heights, this severely affects the watch industry. This metal featuring silver-like brilliance along with hardness and corrosion-resistance is commonly used in watchmaking. The value of the treatment developed by the company in La Chaux-de-Fonds is that it offers identical aesthetics and similar properties to rhodium: identical colour, excellent resistance to corrosion, thin and uniform coating, full reversibility as well as a competitive price.

The company has been working for several years to propose an alternative treatment to rhodium for which a patent was issued in 2019. Rhodium resources are particularly limited, at around 25,000 tonnes/year, extracted mainly in South Africa (80% of world production). Its current price is reaching record highs: at the end of March 2021, it was 15 times more expensive than gold, with its price 35 times higher than five years ago.

The advantage of this new treatment is its nanometer-level conformity and uniformity. It therefore meets the highest requirements of microtechnology in every respect and is an advantageous replacement for rhodium, particularly on tungsten monobloc oscillating weights.

Founded in 2004, Positive Coating stands out for its development of innovative solutions in the field of surface treatments based on PVD (Physical Vapor Deposition) and ALD (Atomic Layer Deposition) technologies, advanced physical and chemical treatments. Operating at the heart of a demanding microtechnology industry, the company contributes to the development of excellent technological products.

August 19, 2021

News

News