After developing the lead-free barrel with Bioflex spring, the firm has taken a new step forward with the acquisition of a unique machine capable of automatically assembling a complete barrel. Responding to both environmental and functional challenges, the lead-free barrel and Bioflex spring launched in 2024, have enabled the Biel/Bienne-based company to meet the expectations of brands wishing to reduce their ecological impact while complying with international standards on the elimination of toxic substances.

Bioflex is an innovative alloy with mechanical properties far superior to those of traditional Nivaflex springs, such as increased resistance to fatigue and improved elasticity, which contributes to greater movement precision and an increased power reserve.

An essential element of the mechanical movement, the barrel plays a major role in the storage and transmission of energy. It is composed of several distinct elements: the drum, the spring, the arbor and the cover. Until now, these different components were assembled by hand.

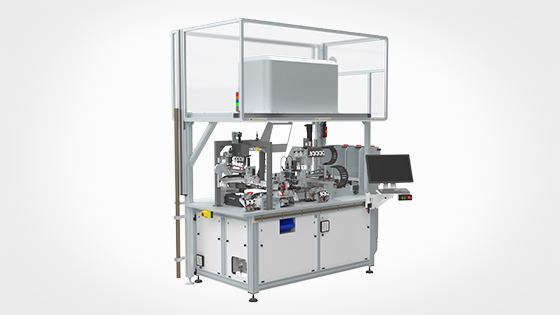

In the future, this assembly will be done automatically thanks to a revolutionary machine that will soon be operational in the workshops of Générale Ressorts in Biel/Bienne. “This is the biggest machine investment in the history of Générale Ressorts”, says CEO Alberto Sicco. “Thanks to the ingenuity of Petitpierre, another company in the Acrotec Group, we will benefit from a machine that is unique in Switzerland, which can adapt to the specific characteristics of each barrel and produce large volumes, some 250,000 assembled components per year! This is a major advance that corresponds to the brands’ desire for greater automation.”

The advantages of this new assembly machine are manifold: time savings for large volumes, better quality, improved repeatability, enhanced traceability with automatic control at the exit, greater precision, not to mention the advantages of automatic drum lubrication and arbor oiling.

The cost savings are also significant for customers, a fact that – depending on the tooling costs required for assembly of specific barrel – can quickly make a financial difference.

February 27, 2025

News

News