Gone are the days when microtechnical parts were cleaned by hand in bins of extremely variable cleanliness. No more optical measurement in dedicated rooms far from the machines.

By imagining two independent small-sized modules – Drop & Lumen – to be placed directly next to the bar turning machines in order to clean and measure components in the demanding workshop environment, Petitpierre is innovating and completely rethinking these two fundamental stages of bar turning.

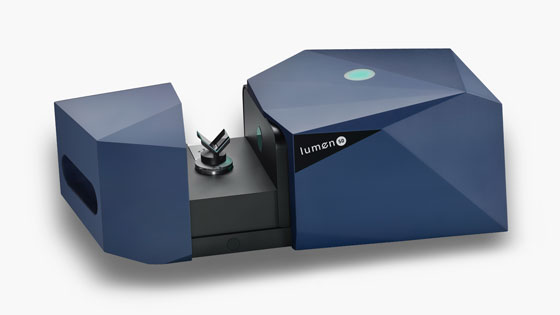

Lumen, the solution for optical measurement directly at the machine exit, enables instant measurement of parts up to 15mm in size by means of simple and fast vertical or horizontal positioning (depending on whether they are revolving or plate-type parts). The component is immediately detected and measured after smart analysis of the cleanliness of the base. A maintenance kit for the lenses and the base is also provided. Lumen’s many adantages include the interchangeability of the bases, the speed of these swaps, the absence of tools and adjustment-free changes.

To ensure correct measurement, the parts must be perfectly cleaned. Drop, the automatic single cleaning module, ensures repeatability and quality, as well as perfect synchronisation of the cleaning and measuring processes, thanks to exactly the right amount of solvent for each part and one-time use of benzine. Three simultaneous cleaning operations are possible and facilitated by an easy-to-use, automatically cleaned vacuum gripper adapted to the parts.

August 25, 2022

News

News