Backed by 133 years of uninterrupted activity, this independent family electroplating business is now headed up by two young managers.

Founded by Louis Estoppey in 1880, Estoppey-Addor SA is Switzerland’s oldest electroplating business. When it was first set up, the workshop specialised in gilding movements and wheels for watchmaking. In 1908, Louis died and his widow Lina, née Addor, took over the business, assisted later on by the eldest of her four children, Paul-Henri. Over the years, the company grew and Henri, the founder’s grandson took over the reins in 1947. His son Olivier – in the fourth generation – followed him in 1987. During the seventies and until 1980, the crisis in the watchmaking industry made diversification imperative. The sectors of electronics, surgery, connection technology and micromechanics filled out the order book and enabled the enterprise to get through this bad patch. Olivier died at the age of 40 in 1996 and the management was entrusted to his brother-in-law, Jean Hirt, who took over pending the arrival of the new generation. One year ago, the post of managing director was entrusted to Sandrine and that of technical and sales director to Cyril, both of them Olivier’s children. Proud of passing the baton to the new generation, Jean Hirt went on to occupy the post of deputy director, head of finance and Chairman of the Board of Directors for a transitional phase.

Electroplating is a speciality dating back for more than 3,000 years. The technique consists in depositing a material on an object by the electrolysis process. It was used for the very first time by the Egyptians to decorate art objects in red copper. Gilding, silvering and nickel-plating by the electrodeposition technique seem to have been applied for the first time to watchmaking articles in Switzerland. In over a century of existence, this method has undergone enormous evolution involving galvanic baths with ever better performance characteristics and deposited materials which confer great hardness and an attractive aesthetic aspect on classical metals. For decorative treatments (depositing gold, palladium, nickel or silver) or technical processing (to increase resistance to wear and corrosion), Estoppey-Addor takes a highly professional approach. The company also offers a number of innovative and exclusive treatments such as Hardalloy or Trigold (depositing gold-copper-indium, an attractive substitute for the traditional cadmium).

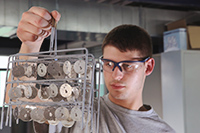

With 25 employees, including three electroplating apprentices, Estoppey-Addor currently dedicates some 60% of its activity to watchmaking and jewellery. It also covers the fields of profile-turning, precision mechanics, medical and dental technology, aeronautics and electronics. Its clients are for the most part sub-contractors for whom the Bienne-based company takes on great challenges every day. Elecroplating in fact takes place at the end of the workpiece processing chain with very short order performance deadlines (3 to 4 days). The company must therefore show great flexibility in planning its work and be highly reactive. It has also developed close contacts with its clients in order to better understand their wishes and so live up to their expectations as effectively as possible. In parallel with its electroplating activity, Estoppey-Addor also has a sand-blasting and sapphire-blasting workshop.

Because electroplating requires perfect control over the quality of the rinsing waters which are used and extremely rigorous waste management, the directors have done everything in their power to make the company as ecological as possible. Already benefiting from ISO 9001 certification in 1996, followed by ISO 14001 in 2008, Estoppey-Addor has set up its own water treatment station (STEP). Rinsing water is treated at basement level; once it has been purified, it is returned to the baths on the upper floors. Heavy metal residues are concentrated in monometallic sludge which is then dried and delivered to companies that specialise in this type of recycling. Since the inauguration of this new ultra-modern facility, the company’s water consumption has been divided by six.

Today, more than at any time in its history, Estoppey-Addor SA – not to be confused with a competitor company bearing a similar name located in Aegerten – is proud of asserting its difference. Because of its size, it is in a position to maintain close ties with its clients and offer them highly personalised services, ranging from one-off pieces to big series.

Three questions to the new generation

Sandrine Estoppey, a trained business manager, has always worked in the electroplating sector. When she was still at school, she did small holiday jobs in the family business. Cyril, her brother, learnt the trade of electroplater in order to take over the technical management of the company.

FH: Did it seem self-evident to you, as a member of the fifth generation, to take over the management one day?

Sandrine and Cyril: Things have never been imposed on us. They happened of their own accord, like a certainty.

FH: How do you see the future of Estoppey-Addor?

Sandrine and Cyril: The company is sound and we will do everything possible, each in our respective field, to ensure its permanent survival. We still have ways and means of developing our activities and we are constantly reflecting on new treatments and solutions which can be offered to our clients.

FH: How do you feel in your new managerial roles?

Sandrine and Cyril: At our age this is obviously a great challenge, but we certainly feel at ease and confident. We maintain very good relations with our uncle Jean Hirt, so that this transition is taking place smoothly and without any break in continuity. We can also count on the precious support of Jan Boesch, member of the Management Committee responsible for Human Resources and the Management System, who has been working at Estoppey-Addor for 17 years.

August 21, 2013

News

News