At the dawn of the 1970s, the Swiss Federation of Watch Manufacturers’ Associations (FH) initiated a wide-ranging reliability study of watches resulting in the Chronofiable test procedure, which today is thirty years old.

It was on the basis of a wide-ranging reliability study carried out by the FH in the 1960s and 1970s on successive batches of 1,000 and 2,000 watches worn on the wrist that the Chronofiable reliability test procedure was developed by a team of technicians, leading to the creation of the Swiss Watch Industry Reliability Test Centre (CCF SA).

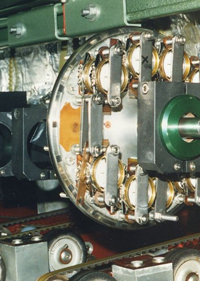

With a factor of acceleration of eight, 21 days of Chronofiable testing correspond in principle to six months of wear on the wrist, with the application of calibrated shocks, linear accelerations of between 250 and 5,500 m/s2 (25 g to 550 g), angular accelerations, and also variations in temperature and humidity.

In 1985, thanks to the support of several leading watch manufacturers, the personnel and equipment of CCF SA were taken over by Laboratoire Dubois, with Chronofiable becoming a department of the latter and also a registered trademark. Today the Chronofiable procedure is an essential step on the path to approval and qualification of the products of many manufacturers, not least among which is the award of the Fleurier Quality Label. Comparisons made with watches worn at the time the procedure was developed, as well as thirty years of experience involving thousands of tested timepieces, show an excellent correlation between the behaviour of watches as worn on the wrist and the results of the Chronofiable reliability test.

To ensure good reproducibility of test conditions and to be in a position to make consistent long-term comparisons, equipment is regularly updated, serviced and calibrated; test parameters, unchanged for 30 years, are still exactly the same.

In an era when development times of new products are growing ever shorter, the duration of an ageing cycle may appear quite long (three weeks of testing for one cycle, plus the time needed to carry out initial and final operating tests). Most users are nonetheless satisfied and even insistent that this situation should remain unchanged in order to guarantee stability in terms of ageing conditions and comparison of the behaviour of movements. The trend towards shorter cycles in the development and approval of a new product is not always beneficial when it comes to verifying its reliability by simulating conditions of use, particularly when the target is a service life of more than ten years for "top of the range" products.

However, some functions and components are less sensitive to variations in test parameters and their reliability is relatively unaffected by the frequency of constraints imposed. Examples include the tightness of back cover screws and casing-up screws, as well as the integrity of dials and hands, which can be tested more quickly through the accelerated application of multidirectional shocks. Current Chronofiable equipment allows a reduction in the timescale of the test procedure, meaning that a new casing-up concept can be validated in a matter of several days. However this multidirectional impact test, along with other greatly accelerated ageing procedures available on the market, gives little indication as to the overall behaviour of the watch and its movement, with no data currently available to establish with confidence a correlation with actual conditions of being worn on the wrist.

At the end of the 1970s, development of the Chronofiable ageing test resulted from a desire on the part of the Swiss watch industry to have at its disposal a powerful tool with which to determine the reliability of its products. The Laboratoire Dubois and the Swiss watch industry continue to benefit today from this important shared development. It is a very valuable service for an industry anxious to maintain the high level of quality of its timepieces under the demanding conditions of everyday use.

Through the stability of the parameters applied, experience acquired over more than 30 years and the availability of rigorously maintained and updated equipment, the Chronofiable accelerated ageing test makes it possible today, as in the past, to test the reliability of watch industry products with the greatest confidence and under perfectly reproducible conditions.

September 30, 2008

News

News