The production of hairsprings and balance wheels is now fully operational at E2O Innovations and Schwarz Etienne, sister companies forming part of a rare breed of independent manufacturers capable of producing these intricate, labour-intensive and fundamental watchmaking components.

While production itself has been effective for several years – all of Schwarz Etienne’s calibres are equipped with in-house balances and E2O Innovations is already a supplier to a number of watchmaking companies – the process is now completely consolidated. Production capacity has increased to cater for the creation of tens of thousands of watch assortments per year. This makes it possible to market products, whether small or large scale, for third parties.

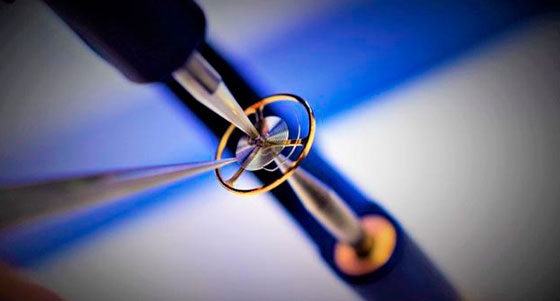

The production of hairsprings, the very heart of the mechanical movement, is one of the most complex crafts of the watchmaking trade, with only a few players in the industry. Extreme precision is required to master this skill with tolerances lower than a micron. Indeed, a difference of 0.1 microns (100 nanometers) on the profile of these spiral springs can have an impact of up to 300 seconds on the daily rate of a movement.

For Schwarz Etienne, this capacity to develop and produce its own hairsprings provides a guarantee of being able to work with the regulating organ of each of its calibres ensuring full control over the whole production and quality process. Meanwhile, for E2O Innovations, this working structure and expertise provides the company with the opportunity to propose an even more extensive range of products, allowing it to develop and produce assortments, whether small or large in volume, and adapted to the needs of its different customers. E2O Innovations’ objective is to continue to enrich its customer portfolio and produce several tens of thousands of assortments over the coming years.

October 19, 2017

News

News